Equipping Innovation

With over 35 years of excellence in manufacturing, AJA International, Inc. is fueling a global golden age of innovation in the world of thin film coating & deposition.

WELCOME TO AJA INTERNATIONAL, INC.

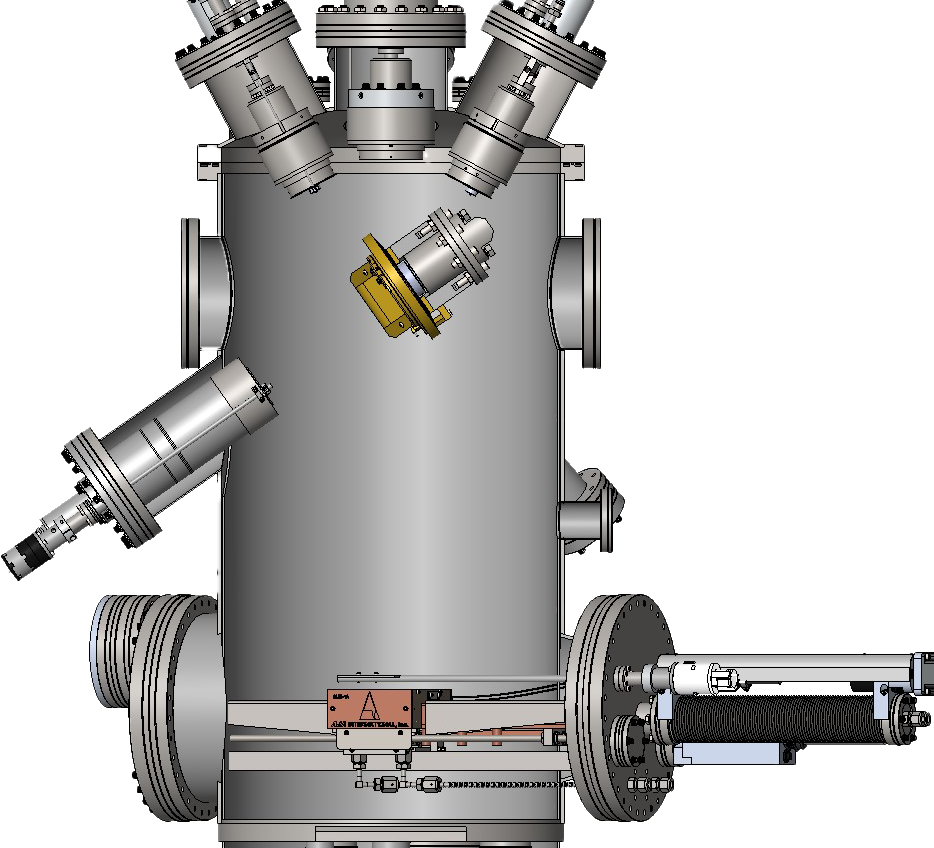

AJA is a manufacturer of thin film deposition systems including magnetron sputtering, e-beam evaporation, thermal evaporation, and ion milling systems. Founded in Scituate, MA, USA in 1989 by William Hale, MBA, BS Physics, the company was established as a supplier of innovative physical vapor deposition (PVD) products. With many systems and magnetron sputter sources shipped worldwide, AJA International, Inc. continues to discover innovative design solutions which are often copied but never equaled. The company truly remains the cutting edge in thin film technology.

SPUTTERING

SYSTEMS

ION MILLING

SYSTEMS

HYBRID

SYSTEMS

EVAPORATION

SYSTEMS

SPUTTERING

SOURCES

SUBSTRATE

HOLDERS

WHAT’S NEW AT AJA

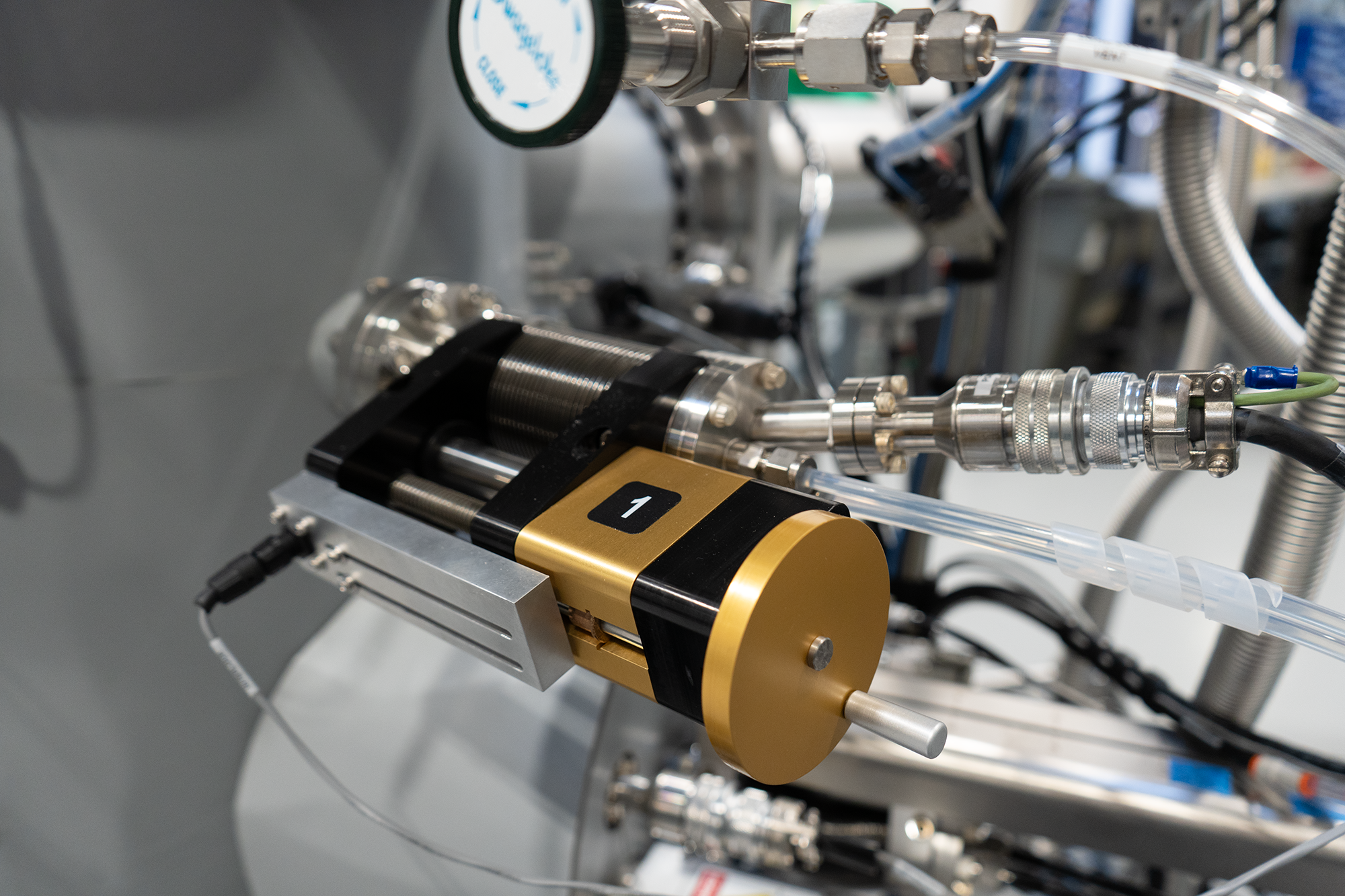

UHV Linear Shift Mechanism

AJA International is pleased to announce an addition to our offerings for advanced components for vacuum systems. Linear motion in vacuum is useful in several applications, and our family of linear shift mechanisms (LSM) offer an excellent solution. They are compact and robust, field-proven over many years of operation in our own thin film deposition systems. The LSM Series offer a variety of options for travel range and motion control. Follow the link below to learn more!

UHV Linear Shift Mechanism:

WHAT’S NEW AT AJA

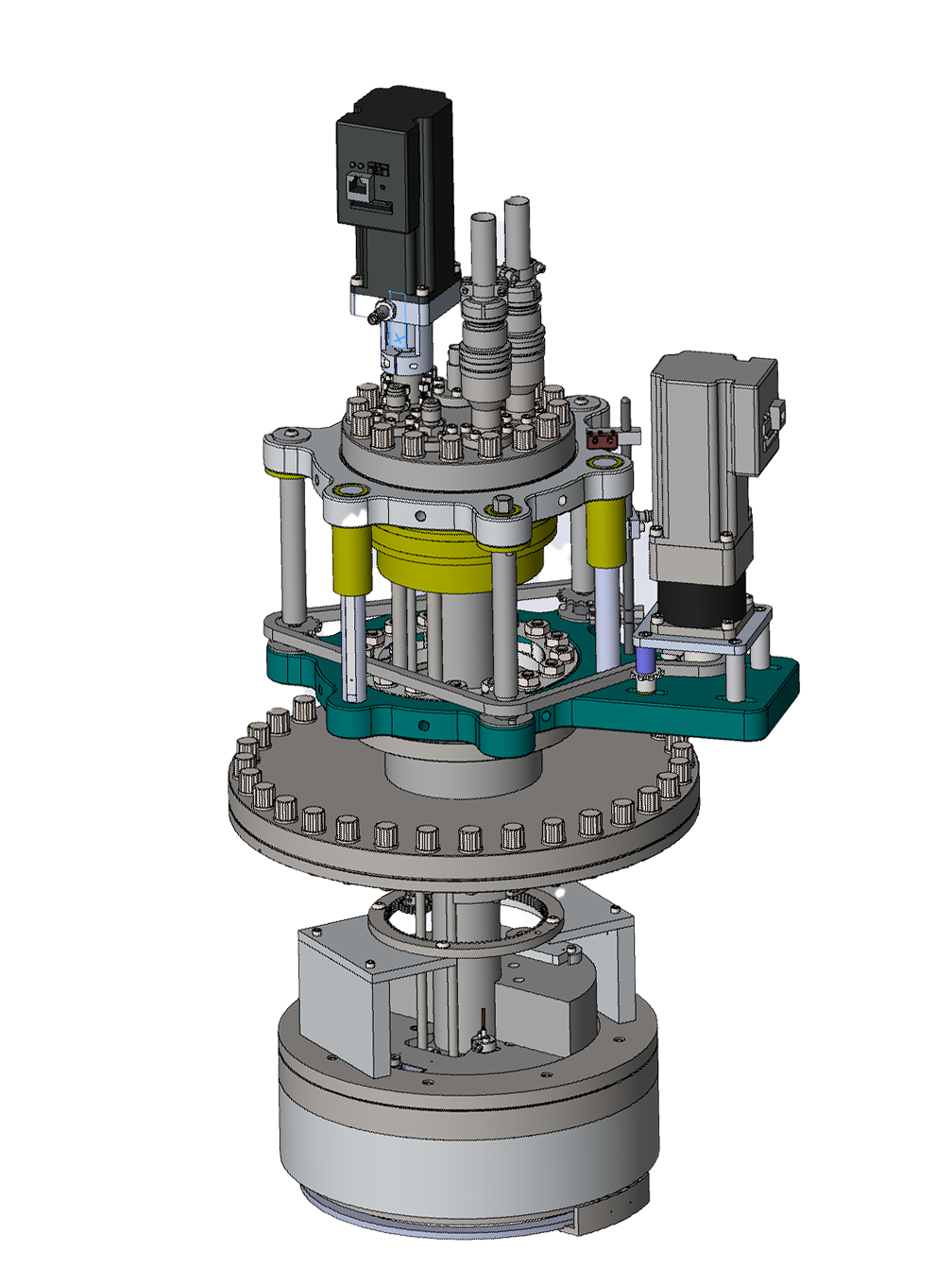

Combinatorial Chemistry Upgrade for Orion Systems

As an addition to our combinatorial deposition toolkit, AJA International now offers an upgrade to existing Orion systems to enable combinatorial chemistry. Multiple distinct specimens of different composition can be deposited onto one substrate, through the use of a mask. The mask or the substrate can be rotationally indexed to provide a circular array of discrete test dots. Combined with our automated recipe execution, up to two dozen samples can be grown on one substrate. Would you like to see learn more about how to dramatically increase materials discovery throughput? Check out the links below!

WHAT’S NEW AT AJA

Applications Hub

We’ve just launched a comprehensive set of Applications pages showcasing how AJA systems drive breakthroughs across research and industry.

Click below to check out each section:

Educational Series – Bring hands-on vacuum science and thin film deposition training into your classroom or lab.

Combinatorial Chemistry – Accelerate high-throughput materials discovery.

Sputter Beam Epitaxy (SBE-6) – Unlock unparalleled control and purity for advanced research.

Spintronics – Achieve MBE-like film quality for next-gen electronics and quantum devices.

Phase-Change Memory – Advance storage innovation with precise thin-film deposition.

HiPIMS – Harness high power impulse magnetron sputtering for ultra-dense, high-quality films.

WHAT’S NEW AT AJA

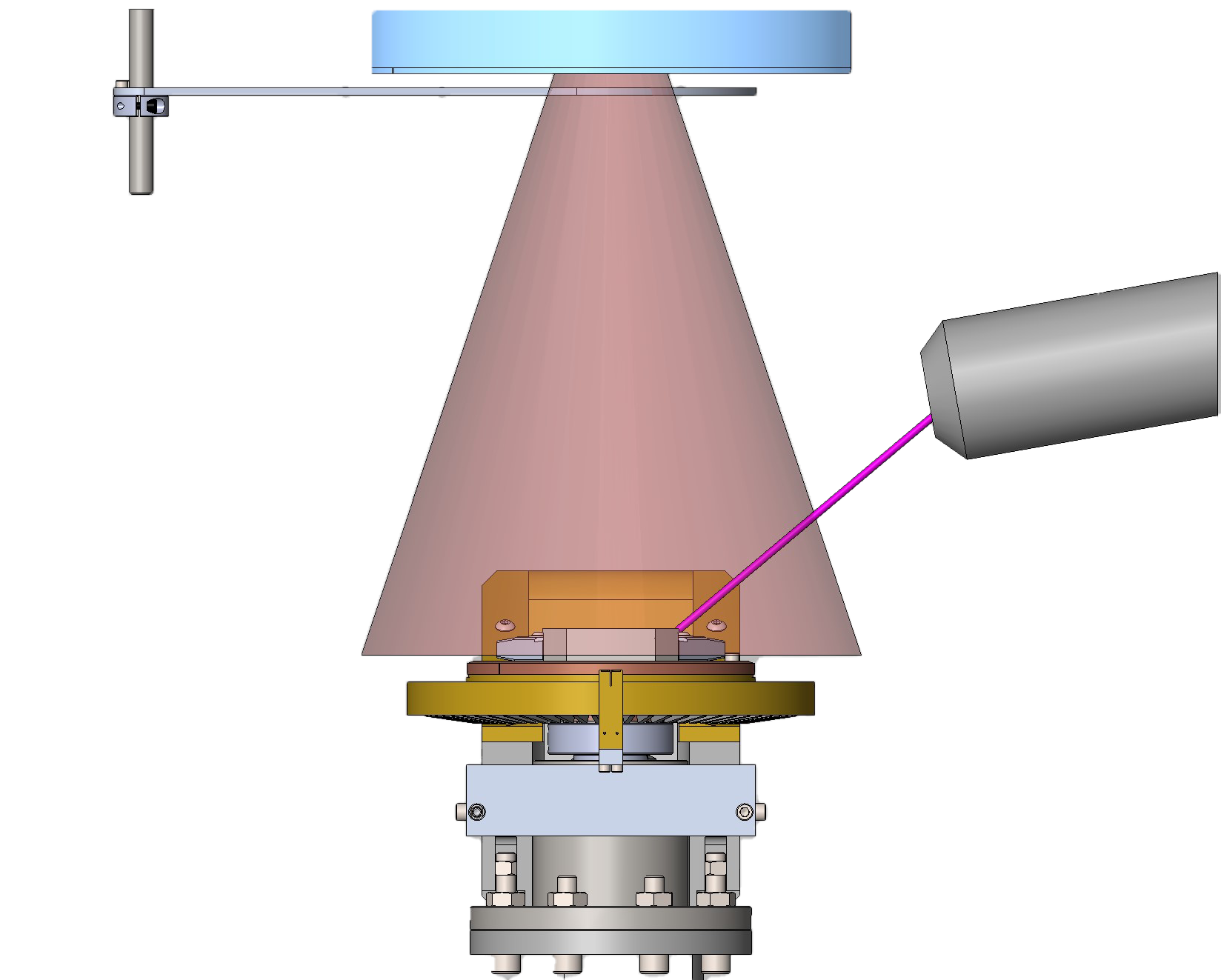

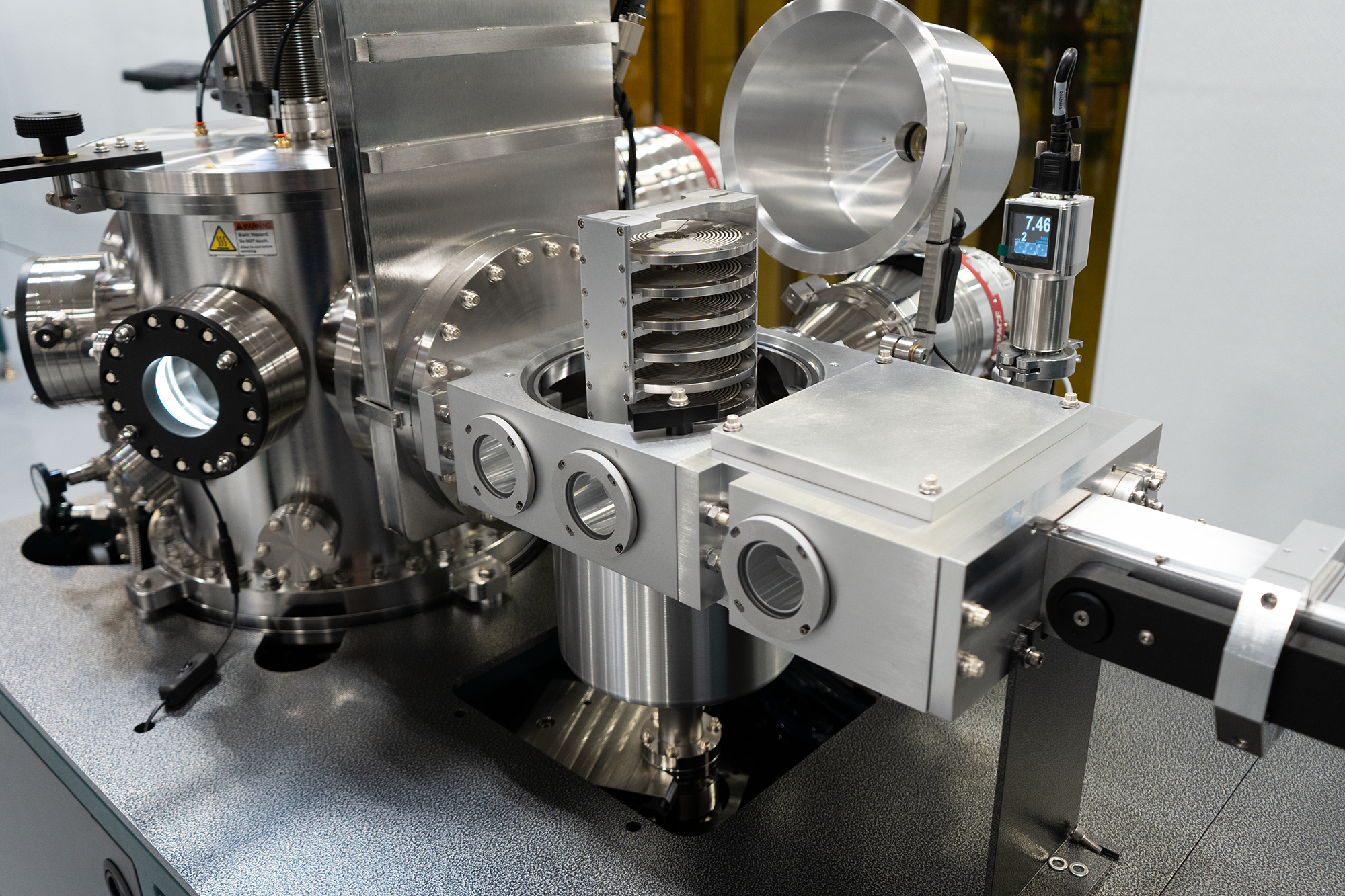

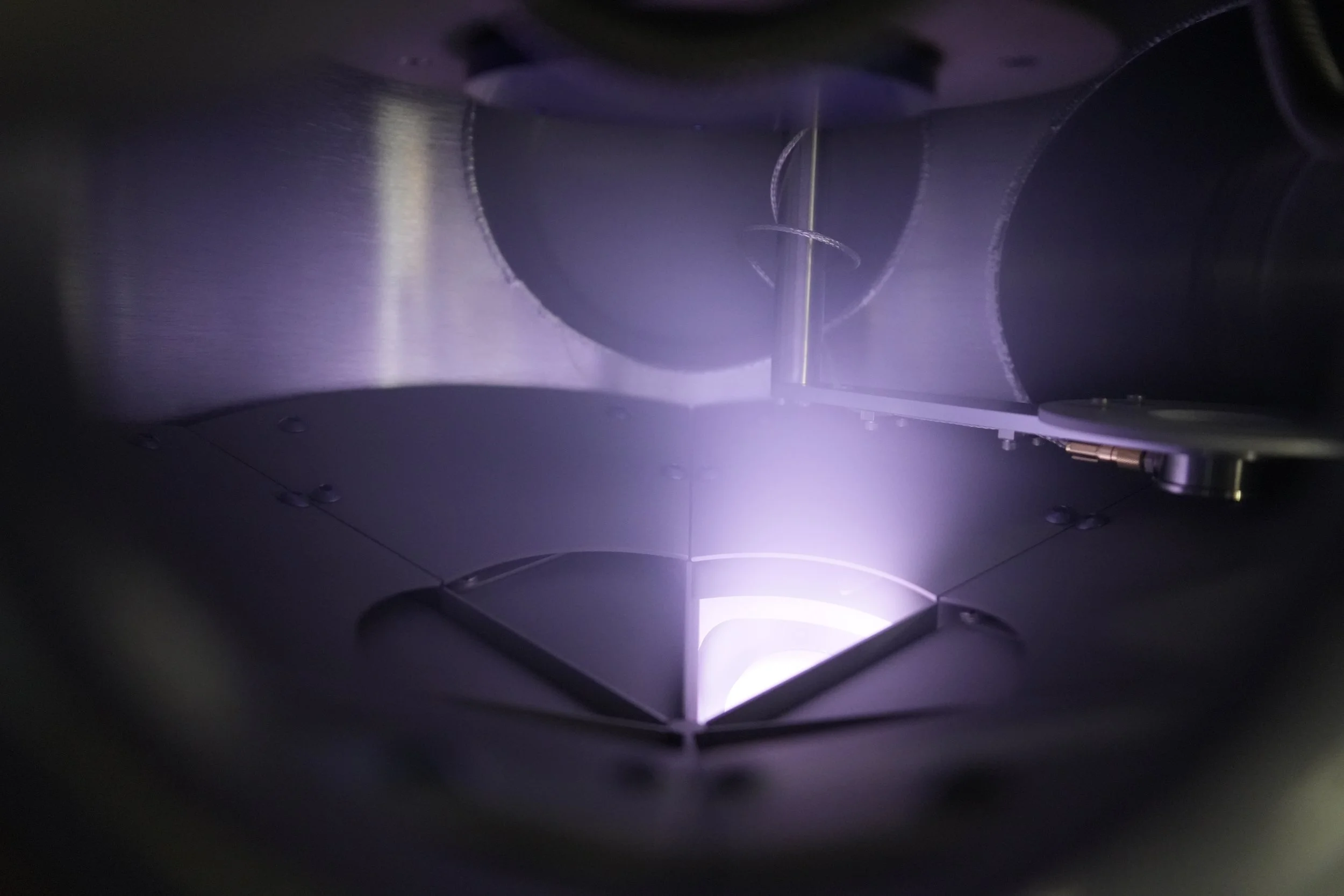

SBE-6 Series Sputter Beam Epitaxy (SBE) Deposition System

The SBE-6 Series Sputter Beam Epitaxy (SBE) Deposition System combines deposition quality that rivals molecular beam epitaxy (MBE) with the ease, flexibility, and lower cost of sputtering. This is accomplished through a unique sputtering geometry, developed through extensive research. The SBE-6 Series enables the co-deposition or sequential deposition of up to six distinct materials while minimizing cross-contamination. The system has proven performance to grow epitaxial films of high crystallinity, precise stoichiometry and atomically flat interfaces. A quartz crystal monitor provides deposition rate calibration from elemental targets, providing the option to precisely form compounds without the expense or difficulty of compound targets. This advanced platform integrates years of refinement in deposition dynamics within AJA International’s proven engineering framework and high-performance components recognized globally for their reliability.

WHAT’S NEW AT AJA

The Educational Series Deposition System

AJA International is excited to partner with educators to design an accessible system dedicated for training the next generation of technology specialists. The Educational Series system features a magnetron sputtering gun for coating as well as RF bias etch on substrates up to 2” diameter. Manual operation mode gives the student direct insight into typical controls of a vacuum process tool. Students can receive hands-on instruction in loading samples, changing sputtering targets, creating thin film coatings, or doing substrate etch for material removal or surface preparation. An available residual gas analyzer provides quantitative insights into the composition of the vacuum environment and its impact on processes. Vacuum science and technology concepts can be taught and demonstrated. The system is almost completely self-contained, requiring only a 110V power outlet and a source of process gas (typically argon). Operation can readily be carried out in a classroom or instructional laboratory. Its low cost, small size, simple loading and unloading and integrated safety features make it an attractive instructional aid that greatly enhances technical education programs.