SBE-6 Sputter Beam

Epitaxy Systems

General Information

AJA International SBE-6 Sputter Beam Epitaxy Systems represent a breakthrough technology in thin film deposition. The sputter guns are oriented in a unique off-axis geometry determined by modeling and proven in practice to provide MBE-like epitaxy for thin film growth. The system is designed to provide maximum utility for growth of highly crystalline thin films with sharp interfaces. These HV and UHV systems are built on the proven ATC Series Platform, from which it inherits many design features and common parts.

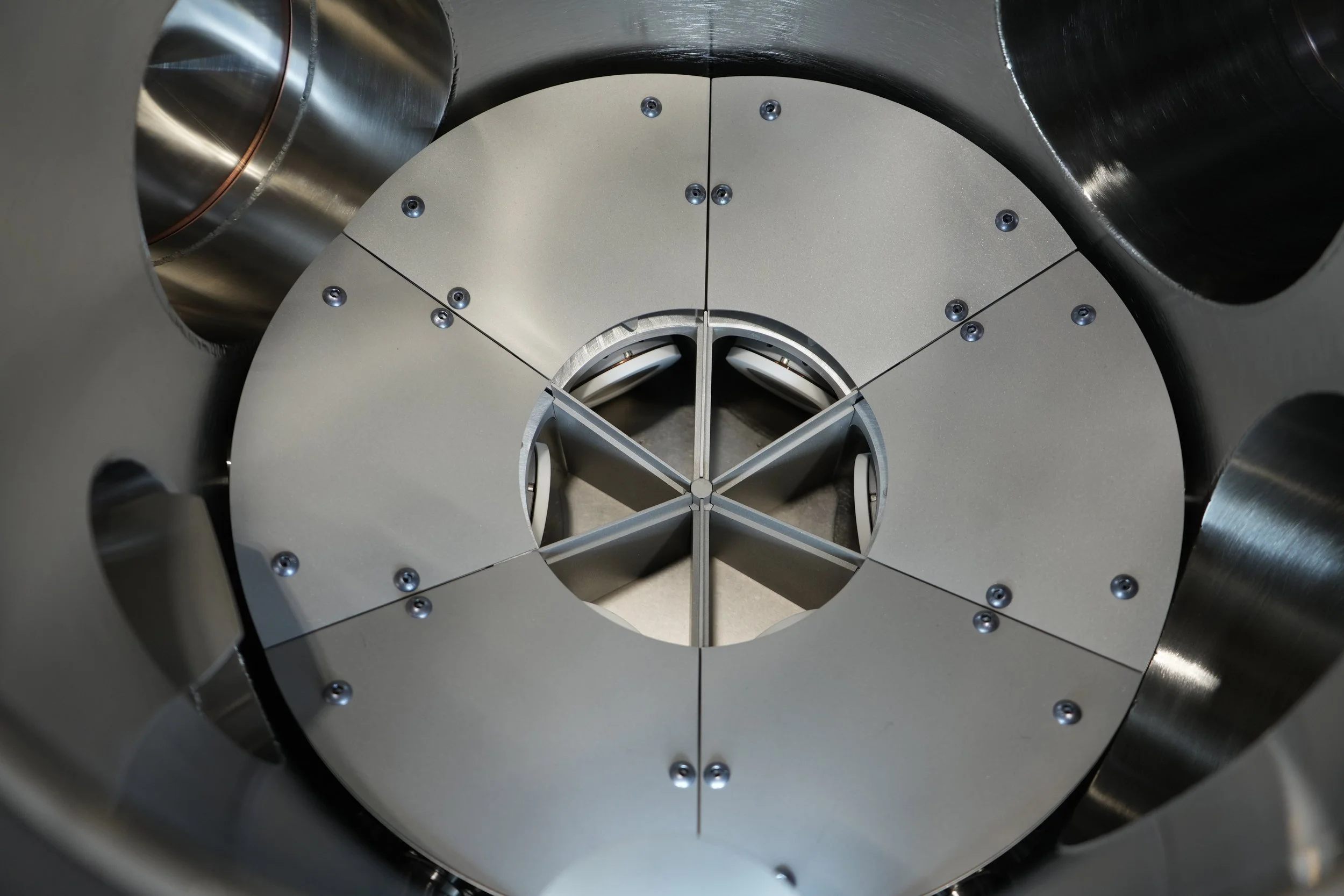

The unique design system design provides six ports arranged around the periphery of the chamber and pointing toward the chamber axis at a moderate angle below horizontal; tilting guns are available, to adjust this angle. The gun enclosures further have wedge-shaped side openings that allow only off-axis emitted species to reach the substrate. The geometry is optimized to exclude high-energy ions from reaching the substrate, providing the MBE-like growth due to a gentle, low flux of deposition material. Up to six 2” guns – Stiletto (HV) or A300-XP (UHV) can be mounted in the system.

Magnetron Sputtering Source Configurations

The unique orientation of the guns in the SBE-6 sputtering system – not offered by any other manufacturer – traps higher energy sputtered material. (See the accompanying applications page on our website.) The substrate, facing down, has no direct line of sight to the target. Only diffusely scattered material contributes to the deposition. Direct measurement and modeling have historically demonstrated the lower energy of the flux in the off-axis configuration. The six gun-confinement cells and stepper-motor controlled wedge shutters prevent cross-contamination and allow for sequential or co-deposition. The guns are specially designed to prevent shorting, since the head of the gun is exposed (no chimney). This feature prevents flakes of re-deposited material from shorting across the anode-cathode gap, which would require chamber venting and maintenance in systems without this feature.

Gun orientation in the SBE-6. The guns point downward from the horizontal while the sample is above, facing downward.

Top view of the gun cluster. Up to (6) 2” sputtering guns can be housed in the off-axis arrangement.

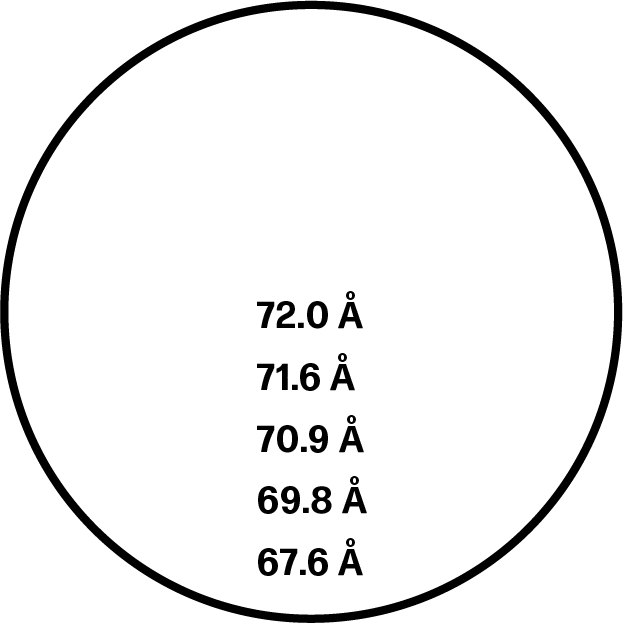

Radial SiO2 film thickness measurements over a 100 mm diameter Si wafer coated in an SBE-6. This film was deposited by a single 2" source in a single run and achieves +/- 3 % uniformity over ~140 mm diameter.

Typical Rate/Uniformity Data

The SBE-6 systems operate with all the 2” guns in the off-axis orientation. The system can deliver uniformity of +/- 3% on 4” substrates. A radial deposition profile with SiO2 on a 4” diameter Si wafer is shown.

Maximum deposition rates are achieved with conductive materials: high sputter yield, excellent heat transfer materials that can be sputtered with DC (most efficient). Slow deposition rates can be expected with materials such as Al2O3 - very low sputter yield, poor heat transfer material and must be sputtered with RF (1/2 the efficiency of DC). Off-axis deposition rates such as in the SBE-6 system are lower than con-focal deposition rates depending on substrate size and system configuration. For example, a measured rate for SiO2 deposition at longest working distance in the system is 1.1 Å/min. At 20 cm lower the rate increases to 3.1 Å/min.

Substrate Holders - Heating/Cooling

The SBE-6 systems utilize motorized, rotating substrate holders to achieve excellent uniformity, allow the co-deposition of alloy films or sequential deposition of pristine, ultra-thin film multilayers. Substrate heaters are available to reach up to 1000°C and feature reactive gas injection rings, RF/DC bias capability, in-situ manual or motorized Z motion (for working distance adjustment and load-lock transfer) and in-situ mask exchange (available only with certain configurations).

Cooled substrate carriers utilizing either water or LN2 are also available depending on the application requirement.

A wide variety of custom substrate holders have also been designed over the years. Speak with us about your special requirements.

Phase II-Au Computer Control

The AJA LabVIEW based Phase II-Au computer control system is used on all Deposition Systems. This straightforward, user-friendly control system utilizes a large 22” articulating screen with wireless keyboard and mouse. The back panel of the hardware module is populated with connectors to interface to all aspects of the sputtering system and to allow for easy future "plug and play" upgrades/expansions.

The Phase II-Au control system allows the user to operate in either the “manual mode” or the “automated processing mode.” In the, “automated processing mode” the user designs "process layers” which are then compiled and saved as a “process” to be executed with a single command. The system allows up to 104 unique user entry points which are accessible only by password, limiting access to a user’s process layers and thereby preventing unexpected corruption of a user’s saved processes. Special “soak layers” can be easily incorporated into the process. Adjustable time base data-logging to a Microsoft Excel spreadsheet is standard. Remote preparation of new processes in a Microsoft Excel spreadsheet emulator format is available as an option.

The standard Phase II-Au control system will accommodate up to (5) DC power supplies, (4) RF power supplies, (1) 4-way DC switchbox, (1) 4-way RF switchbox, (4) process gases, (24) Valves/shutters, (1) DC ion source, downstream closed loop automatic pressure control, substrate rotation and substrate temperature control. Processes are aborted if plasma is not detected, substrate temperature, process gas or chamber pressure is out of range.